As AI continues its inexorable evolution, it seems that no sector of our economy has been left untouched. This has been especially true in the area of manufacturing. Businesses now talk about Smart Manufacturing when referring to their production processes.

According to a recent Google Cloud report, almost two-thirds of manufacturers worldwide had incorporated AI-based solutions into their daily operations, with automotive and OEMs being the top industries to do so. The main area that AI is deployed in is quality inspection, followed by risk management, supply chain management, and production line quality checks. Through automation, machine learning, and AI, smart manufacturing has been transforming traditional operations to achieve higher efficiency and productivity.

This trend of adopting AI solutions can be clearly seen within Taiwan’s fastener industry, especially within the automotive fastener market. Taiwan is currently the world’s third largest exporter of fasteners with over a thousand manufacturers across the country.

For quality inspection, many companies in the fastener industry still use traditional automated optical inspection (AOI) systems that adopt a rule-based model. Despite being commonly used, this approach has two major disadvantages. First, the system is not very effective in dealing with random defects in the production process due to its predefined rules. Second, traditional AOI systems are often set with strict parameters, leading to high false positive rates and many good products being discarded.

Related Reading: Embracing the Era of the Super-Aged Society with ASUS Smart Healthcare Solutions

In response to these challenges, many companies have been considering AI and AOI integrated smart detection systems. However, the threshold for adopting industrial AI solutions remains high because of the complicated AI application frameworks seen in many solutions on the market.

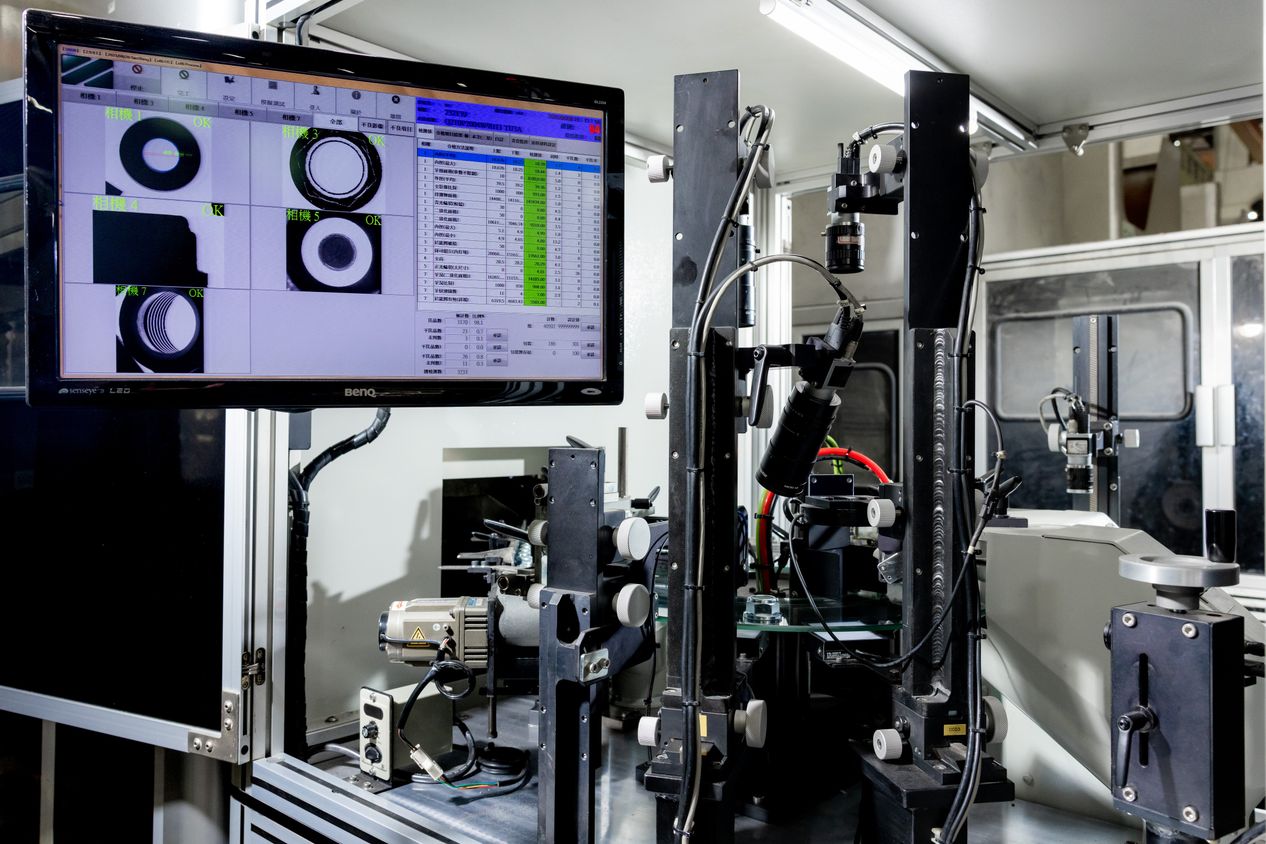

To lower this threshold, ASUS has developed AISVision, an easy-to-use AI toolkit and software development kit (SDK) for computer vision, model training, and inference. By integrating the various tools required by industrial customers into a single platform, AISVision greatly simplifies quality inspection and increases operational efficiency.

Case study: AISVision in San Shing Fastech

A perfect use case of AISVision can be seen at San Shing Fastech, a leading Taiwan fastener company that is one of the largest manufacturers of steel nuts worldwide. In recent years, San Shing Fastech has expanded its operations and devoted itself to high-value automotive screws and nuts.

As an automotive supplier, it is imperative that the company ensure zero-defects in its quality management. However, the previous process that the company was using for quality inspection was often time-consuming and resulted in higher production costs. As a result, San Shing Fastech decided it needed to upgrade to an AI and AOI integrated smart detection system.

This is what led them to consider ASUS AISVision.

There were three reasons for this choice. First, ASUS has a sufficiently large-scale business that can ensure long-term services to its customers. It also had significant experience implementing AISVision across many different industries, meaning it was fully prepared for the challenges San Shing Fastech faced and was able to provide them with a comprehensive service.

Second, ASUS’s AI solutions continue to enhance value over time. AISVision software has an inference model that allows it to not only identify defects quickly, but also gives it the ability to learn and retrain itself. As the training datasets accumulate over time, AISVision continuously optimizes the model to prevent a high false positive rate in the quality inspection process – reducing any unnecessary costs.

Thirdly, ASUS AISVision has secondary development functionality and is designed to be simple and intuitive to use. This allows users to easily customize the existing software and modify it according to the needs of their business. As a result, San Shing Fastech gained the ability and flexibility to design and manage the system themselves after it was implemented. Specifically, the company was able to take over the integration, upgrading, revision, and maintenance of its in-factory IT system sorting equipment.

With help from ASUS during the integration period, San Shing Fastech successfully launched its next Gen AI AOI system in May 2023. The fastener company is also planning to extend this AI framework to the front end of its production line, with the goal of further reducing costs and providing better operational efficiency.

A complete toolkit

ASUS is committed to providing AI-driven software and hardware smart manufacturing solutions that cater to the needs of enterprises and the industry as a whole. Leveraging our extensive experience from the deployment of the first AISVision, we recently launched an upgraded version that aims to further simplify user experience, enhance inspection quality, and significantly reduce in-line production inspection times. ASUS will continue to improve and develop new versions of AISVision, along with other industrial AI solutions, to keep up with ongoing trends and meet the ever-evolving challenges of business.

About ASUS

ASUS is a global technology leader that provides the world’s most innovative and intuitive devices, components, and solutions to deliver incredible experiences that enhance the lives of people everywhere. With its team of 5,000 in-house R&D experts, the company is world-renowned for continuously reimagining today’s technologies. Consistently ranked as one of Fortune’s World’s Most Admired Companies, ASUS is also committed to sustaining an incredible future. The goal is to create a net zero enterprise that helps drive the shift towards a circular economy, with a responsible supply chain creating shared value for every one of us.